Understanding the Cutting Object of the CO2 Laser Cutting Machine

Unveiling the Mystery: What Does the CO2 Laser Cutting Machine Cut?

When it comes to precision cutting and unmatched efficiency, the CO2 laser cutting machine is a game-changer. Designed with advanced technology and the capability to cut a variety of materials, this cutting-edge equipment has revolutionized the manufacturing and fabrication industries. But what exactly is the cutting object of the CO2 laser cutting machine? Let’s delve into this question and unlock the intricacies of its cutting capabilities.

The Versatility of the CO2 Laser Cutting Machine

At the core of its functionality lies the versatility of the CO2 laser cutting machine. This modern marvel is adept at cutting through a diverse range of materials, including:

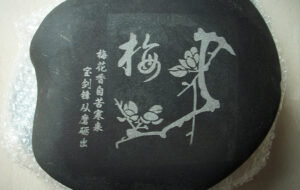

1. Organic Materials

From wood to acrylic, the CO2 laser cutting machine demonstrates remarkable proficiency in handling various organic materials. Whether it’s precise woodwork or intricate acrylic designs, this machine operates with unparalleled precision, making it a go-to choice for many craftsmen and manufacturers.

2. Non-Metallic Materials

The CO2 laser cutting machine exhibits remarkable versatility in its ability to cut through an array of non-metallic materials, including:

a. Textiles

With its precise and focused laser beams, the CO2 laser cutting machine can intricately cut through various textiles, such as cotton, silk, and nylon. This capability is particularly beneficial for industries that require precise and intricate fabric patterns, ensuring impeccable quality in the final products.

b. Leather

The CO2 laser cutting machine showcases exceptional proficiency in cutting through leather materials, irrespective of their thickness or texture. This feature is highly advantageous for leatherworking industries, enabling the creation of intricately designed leather products, ranging from intricate patterns on clothing to detailed engravings on leather accessories.

c. Plastic

From acrylics to PVC, the CO2 laser cutting machine is adept at precisely cutting through various types of plastics. This capability makes it a valuable asset for industries involved in plastic fabrication, allowing for the creation of intricate plastic components and products with unparalleled precision and quality.

d. Rubber

The CO2 laser cutting machine is also well-suited for cutting rubber materials, offering an efficient and precise solution for industries that require accurate shaping and cutting of rubber components. Its ability to handle different types of rubber, including silicone and natural rubber, ensures a seamless cutting process, resulting in high-quality rubber products for various applications.

e. Composite Materials

Apart from individual materials, the CO2 laser cutting machine can effectively handle various composite materials. These can include laminates, reinforced plastics, and composite fabrics. Its precise cutting capabilities enable the production of complex composite structures and components, catering to the demands of industries that rely on composite materials for their manufacturing processes.

3. Thin Metal Sheets

While primarily designed for non-metallic materials, the CO2 laser cutting machine exhibits a remarkable capability to cut through thin metal sheets with remarkable accuracy. This feature opens up new possibilities for industries where precision metal cutting is a necessity, providing a comprehensive solution for various manufacturing needs.

The Cutting Precision and Accuracy

One of the most significant advantages of the CO2 laser cutting machine is its unparalleled precision and accuracy. By harnessing the power of focused laser beams, this machine can achieve intricate cuts and designs with minimal material wastage. The precision allows for the creation of complex shapes and patterns, catering to the demands of industries that require intricately designed components.

The Efficiency and Speed

In addition to its cutting precision, the CO2 laser cutting machine boasts impressive efficiency and speed. With its swift cutting process, it significantly reduces production time, thereby enhancing overall productivity. This efficiency makes it an indispensable tool for industries that prioritize quick turnaround times without compromising on quality.

Conclusion

In conclusion, the CO2 laser cutting machine’s cutting object extends to a diverse array of materials, showcasing its versatility and adaptability in various industries. With its cutting precision, efficiency, and speed, it has solidified its position as a cornerstone in the manufacturing and fabrication sectors, providing innovative solutions for complex cutting requirements. As technology continues to advance, the CO2 laser cutting machine is set to spearhead further developments, catering to the evolving needs of the industrial landscape.