Submit an inquiry now

You will be responsed by our sales team very soon !

Price range

Shipping rates are constantly changing, please contact us for a real-time quote.

| NO | Name | Parameter | unit |

| 1 | Plane cutting format (length X width) | 600×600 | mm |

| 2 | X axis itinerary | 600 | mm |

| 3 | Y axis itinerary | 600 | mm |

| 4 | Z axis itinerary | 100 | mm |

| 5 | X, Y-axis positioning accuracy | ±0.05/1000mm | mm |

| 6 | X and Y axes | ±0.03/1000mm | mm |

| 7 | Accelerated speed | 0.6G | m/s² |

| 8 | Maximum linkage speed | 30 | m/min |

| 9 | Maximum payload of the platform | 50 | kg |

| 10 | laser power | 1500 | w |

| 11 | Control system | Empower |

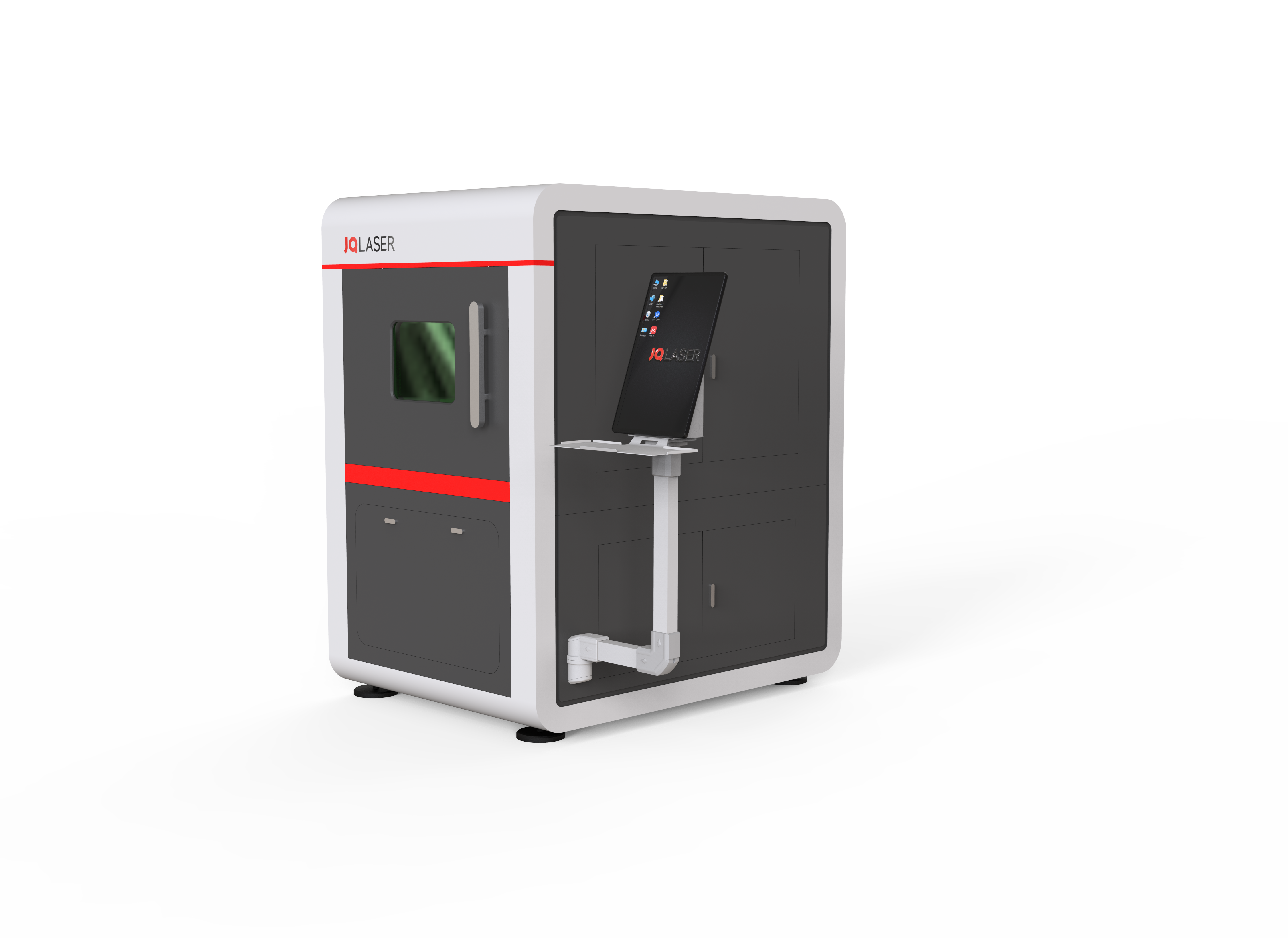

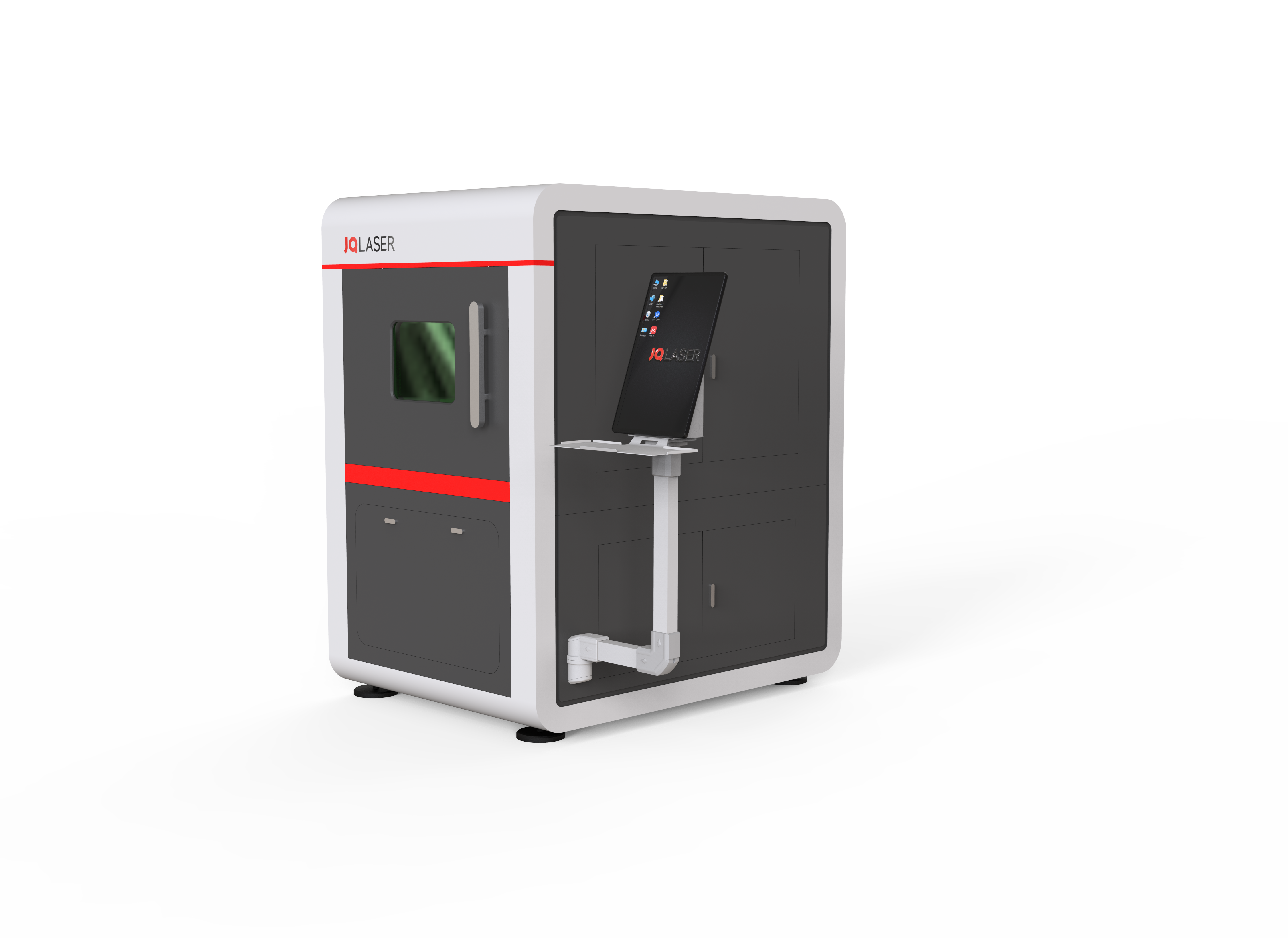

JQ-6060 series optical fiber plate cutting machine mainly includes: machine tool host, control system, laser, chiller, exhaust fan, etc.

2.1 Machine tool main engine part

The main part of the machine tool is the main component of the whole fiber plate cutting machine. The cutting function and cutting accuracy of the fiber plate cutting machine are realized by the main part. The main part is composed of bed body and blade frame, frame beam and Z axis device, funnel drawer, auxiliary system (air road and water), operation table and other parts.

2.2 Electrical control part

The electrical control system of optical fiber flat plate cutting machine is an important part to ensure the running track of various graphics. The general electrical control system is mainly composed of numerical control system and low-voltage electrical system.

The system is equipped with high performance CNC system, which is based on windows operation platform and reliable operation, fast insertion speed, easy operation, good dynamic performance and strong load capacity.

2.3 Low-voltage electrical system

The low-voltage electrical system is located in the electrical control cabinet, which is the interface part of the electrical control of the whole machine. Various original components of the electrical system are produced by well-known manufacturers at home and abroad to ensure that the whole machine is stable and reliable in operation. The drive motor is AC servo motor, AC servo motor is used to drive the X axis and Y axis of machine tool, characterized by good acceleration performance and fast response speed; Z axis of machine tool is feed axis, using AC servo motor (with lock) drive: the Z axis cutting head, characterized by good dynamic response characteristics, both follow-up control and NC control.

2.4 Auxiliary peripheral equipment

Including water chiller, exhaust system, etc.

3.1 Bed body and blade rack

The bed body is made of integral welding, eliminating the internal stress treatment after annealing, and then finishing the vibration time after rough machining, so as to greatly improve the rigidity and stability of the machine tool, and ensure the accuracy of the machine tool. Through the numerical control system to control its AC servo motor drive, the motor drive gear rack to achieve the Y direction of reciprocating motion, to achieve fast movement. The Y-axis linear modules adopt high precision products, which effectively ensure the accuracy of transmission; limited switch control at both ends of the stroke and hard limit device effectively ensure the safety of machine movement.

3.2 X-axis frame cross beam and Z-axis device

The X-axis frame beam eliminates the internal stress after annealing, and then completes the vibration aging after rough machining to ensure the rigidity and stability of the laser head moving member. The bed body is equipped with high-quality linear module, driven by high-quality gear rack drive, so that the Z-axis skateboard can achieve the X direction. In the process of movement, the limit switch controls the stroke to limit the position, and at the same time, there are elastic cushion mechanical limit at both ends to ensure the safety of the system operation.

Z axis device

The Z-axis device mainly realizes the upper and lower movement of the laser head. The upper and lower movement of the laser head is completed by the numerical control system controlling the servo motor, and the motor drives the linear module, which drives the upward and downward reciprocmovement of the Z-axis skateboard. The upper and lower ends use proximity switches to control the travel, to ensure the safety and reliability of the movement. The linear module adopts high quality products to ensure the accuracy of transmission.

The Z axis can be used as a CNC axis for its separate interpolation movement, while linkage with the X and Y axis, and can be switched to follow-up control to meet the needs of different situations. Because the Z axis is also controlled by the CNC system, the Z axis has high accuracy and good stability, thus ensuring the quality of cutting.

After the capacitance sensor in the Z axis device detects the distance between the nozzle to the surface of the plate, the signal is fed back to the control system, and then the control system controls the Z axis motor drives the cutting head, so as to control the constant distance between the nozzle and the plate, and effectively ensure the cutting quality. The cutting head can adjust the focal length automatically or manually, and the position of the focus can be adjusted according to the material and thickness of the cutting material, thus obtaining a good cutting section.

3.3 Electrical control system

JQ-6060 series optical fiber flat plate cutting machine electrical control system is mainly composed of Jiaqiang CNC system, servo system and low-voltage electrical system. The laser cutting machine is equipped with high performance Jiaqiang CNC system, which is based on WINDOWS PC CNC system, with fast insertion speed and convenient operation; servo system is imported AC servo motor and driver, stable and reliable, good dynamic performance, strong load capacity, convenient operation. The machine operation soft key can have different functions in different modes of operation, thus reducing the operation buttons and simplifying the operation panel. Various ways are displayed by the menu to make the operation intuitive.

3.3.1 With a special laser power control function

According to the speed and power parameters set by the operator, the size of the laser power can be accurately adjusted to ensure that the machine tool can still obtain the corresponding best laser cutting power at the different speed of acceleration and deceleration.

3.3.2 Strong processing function

The machine has a variety of processing and auxiliary function instructions, for a variety of complex graphics can be edited by the instructions.

3.3.3 High machining accuracy

Because the machine has good electromechanical drive dynamic performance, so good processing follow, high precision.

3.3.4 Z-axis can be both driven and CNC

In order to solve the problem of cutting quality caused by the uneven surface of the plate, the cutting head (Z axis)

Must follow up to keep the focus constant. Has the same display and control functions as X and Y axes.

3.3.5 Graphic display

With the function of analog graphic display and dynamic graphic tracking display, making the machining more intuitive and easy to monitor and control.

3.3.6 Multiple alarm functions

The CNC system has self-check alarm and automatic protection functions, and also has alarm display and automatic protection for external conditions.

3.3.7 CNC system

The system adopts an integrated structure, and the central control and display operation unit structure is tight. The system is based on the windows CNC system. The display operation unit provides good man-machine interface, display various operation information and operation handle with function keys for machine operation.

3.3.8 Low-voltage electrical system

The low-voltage electrical system is located in the electrical control cabinet, which is the interface part of the electrical control of the whole machine. The power supply, relay, circuit breaker, contactor, servo drive system required by the electrical control system are all installed in the electric control cabinet.

| NO | name | brand | Brand country | remarks |

| 1 | servo motor | Ressaix | China | |

| 2 | Straight line module | China-brand | China | |

| 3 | pneumatic component | Airtac | Taiwan, China | |

| 4 | laser | MAX | China | |

| 5 | laser head | Raytool | China | |

| 6 | cooling-water machine | Mingpin | China | |

| 7 | Low voltage electrical components | Chint, Delixi | China | |

| 8 | IPC | Domestic | China | |

| 9 | Control system | Empower | China | |

| 10 | Proportioner | S MC | Japan |

Random accessories, tools and consumables

Random accessories

| NO | name | specifications | quantity | remarks |

| 1 | X-axis limit switch | One | ||

| 2 | Y axis limit switch | One | ||

| 3 | Z axis limit switch | One | ||

| 4 | High pressure solenoid valve | One | The SMC shall cut the air path | |

| 5 | Water pipe (containing oxygen tube) | 12 Meters | Determine the pipe diameter according to the order equipment. | |

| 6 | High pressure nitrogen pipe | 8 Meters | ||

| 7 | crane span structure | 100×50 | 10 Meters | |

| 8 | Oxygen meter | One | There are 2 throat hoops | |

| 9 | Quick plug joint | a surname | ||

| 10 | Focus protection lenses | Five | 1000w-3000w

(Model of laser head provided according to the order) |

|

| 11 | Collimine protection lens | Two | ||

| 12 | ceramic body | One | ||

| 13 | Cutting copper nozzle (single spray) | Φ1.5、Φ2.0、Φ2.5、Φ3.5 | Each 2 | 1000w-3000w

(Equipped with the laser head model according to the order) |

| Cutting copper nozzle (single spray) | Φ4.0 | One | ||

| Cutting copper nozzle (double spray) | Φ1.2、Φ1.5、Φ2.0、Φ2.5, Φ3.0 | Each 2 | ||

| Cutting copper nozzle (double spray) | Φ4.0 | One | ||

| 14 | Screw, flick, flat pad | Inside the hexagonal:

M4*16, M4*35, M5*20,M6*12,M6*20 M8*25

|

Each 20 | Each type of screws and elastic flat pads are equipped with 20 sets |

Consumptive material

| NO | name | specifications | quantity | remarks |

| 1 | Advanced cotton stick | 20 Roots | ||

| 2 | cellulose tape | 1 Volume | ||

| 3 | paper self-adhesive tape | 1 Volume |

Attachment tools

| NO | name | specifications | quantity | remarks |

| 1 | Toolbox | One | ||

| 2 | Inside the six sides of the wrench | A set | ||

| 3 | shifting spanner | 12 Inch | One | |

| 4 | One-word screwdriver | 3×100 | 1 The | |

| 5 | One-word screwdriver | 6×100 | 1 The | |

| 6 | Phillips screwdriver | 3×100 | 1 The | |

| 7 | Phillips screwdriver | 6×100 | 1 The | |

| 8 | U tray | 8g | One | |

| 9 | Laser phase paper | 297X210mm (black) | 2 Zhang | |

| 10 | eye shield | 1 Deputy |

Random technical data of products

| NO | name | quantity | remarks |

| 1 | Product instructions for use | 1 | |

| 2 | Electrical schematic diagram and wiring diagram | 1 | |

| 3 | List and drawings of vulnerable parts | 1 | |

| 4 | spare parts list | 1 | |

| 5 | certificate | 1 | |

| 6 | warranty card | 1 | |

| 7 | Machine tool shape diagram | 1 |

You will be responsed by our sales team very soon !

Наш отдел продаж ответит вам очень скоро!

¡Nuestro equipo de ventas le responderá muy pronto!

You will be responsed by our sales team very soon !