Submit an inquiry now

You will be responsed by our sales team very soon !

Another aspect of flexibility is the ease of integration with existing production lines. Laser marking machines can be seamlessly integrated into automated workflows, enabling smooth and efficient marking processes without disrupting the overall production flow. This adaptability ensures minimal downtime and maximum utilization of resources.

Additionally, the Laser marking machine’s non-contact nature and non-destructive marking process provide added flexibility when working with delicate or sensitive materials. It eliminates the risk of damage or deformation, allowing you to mark intricate details on fragile items without compromising their integrity.

A laser marking machine is needed for its ability to provide permanent and precise markings on various materials, offering versatility, high speed, customization options, and improved traceability for industries.

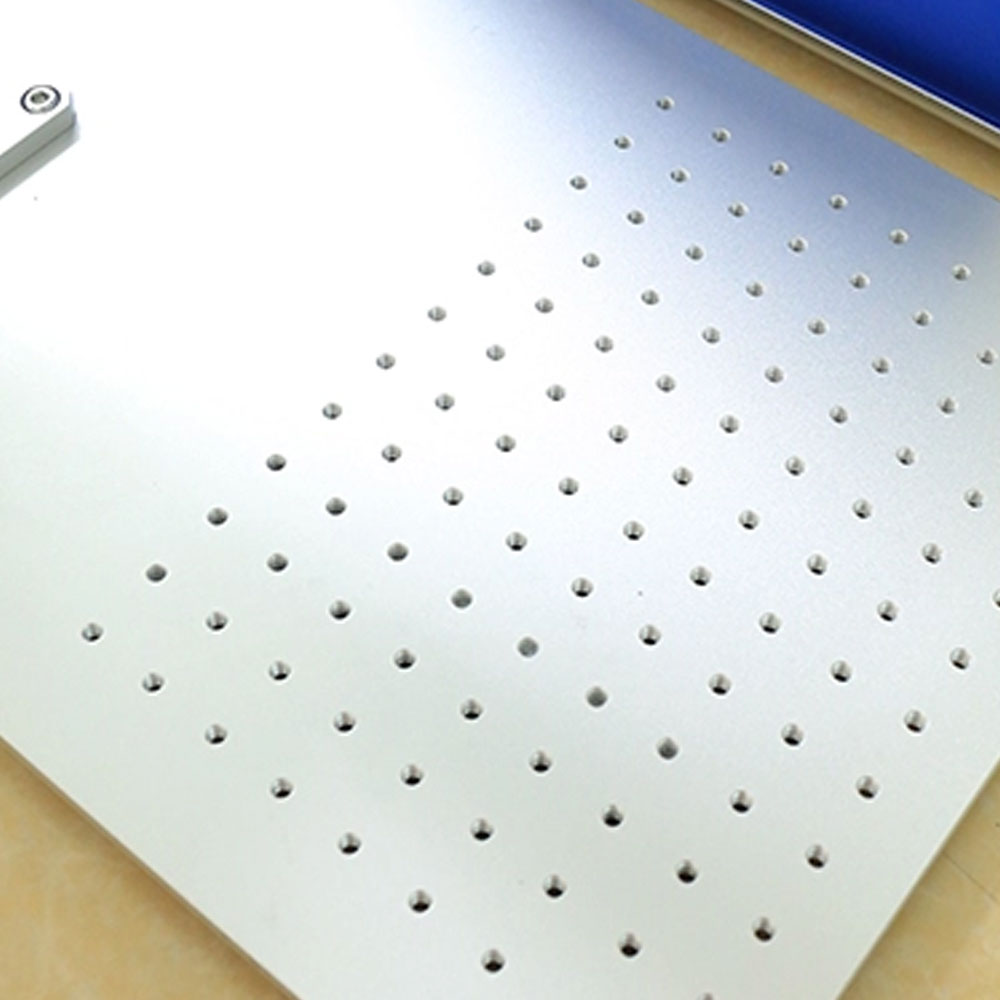

Aluminum working table.

Flat and smooth

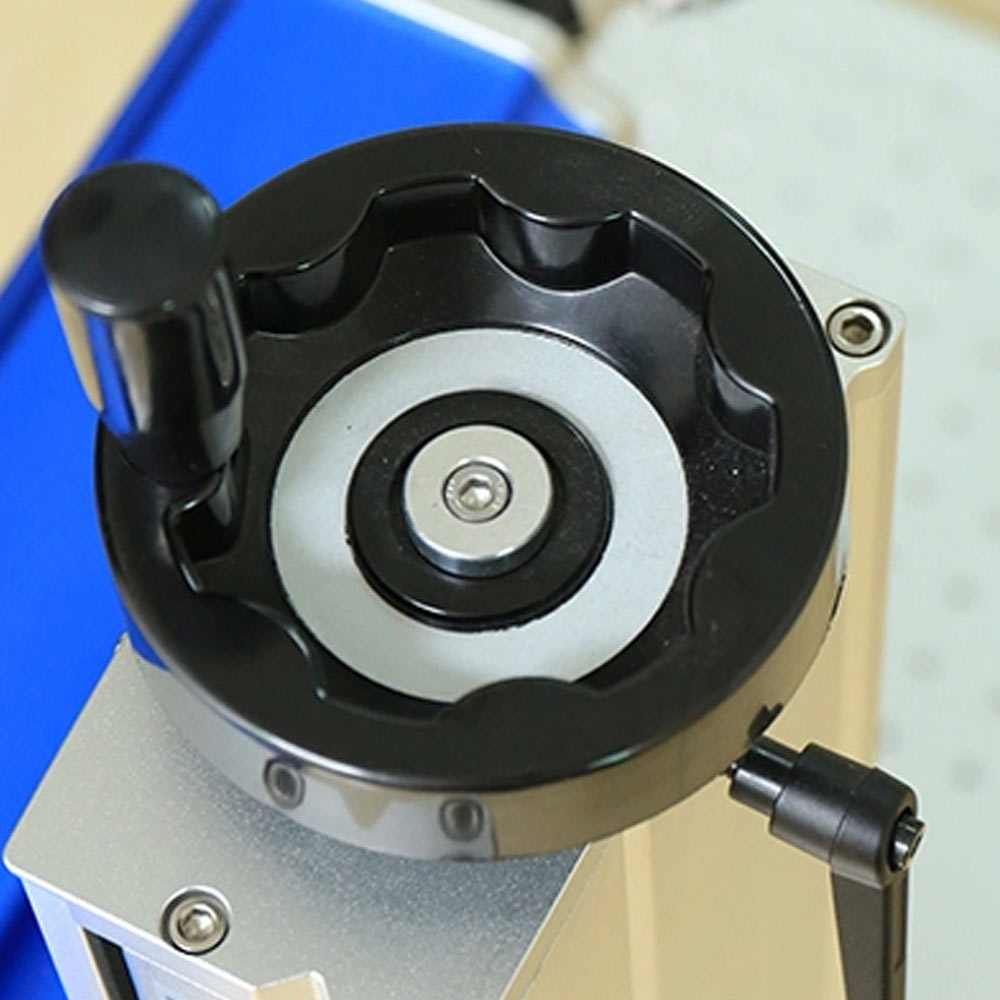

compact structure

flexible processing direction adjustable control

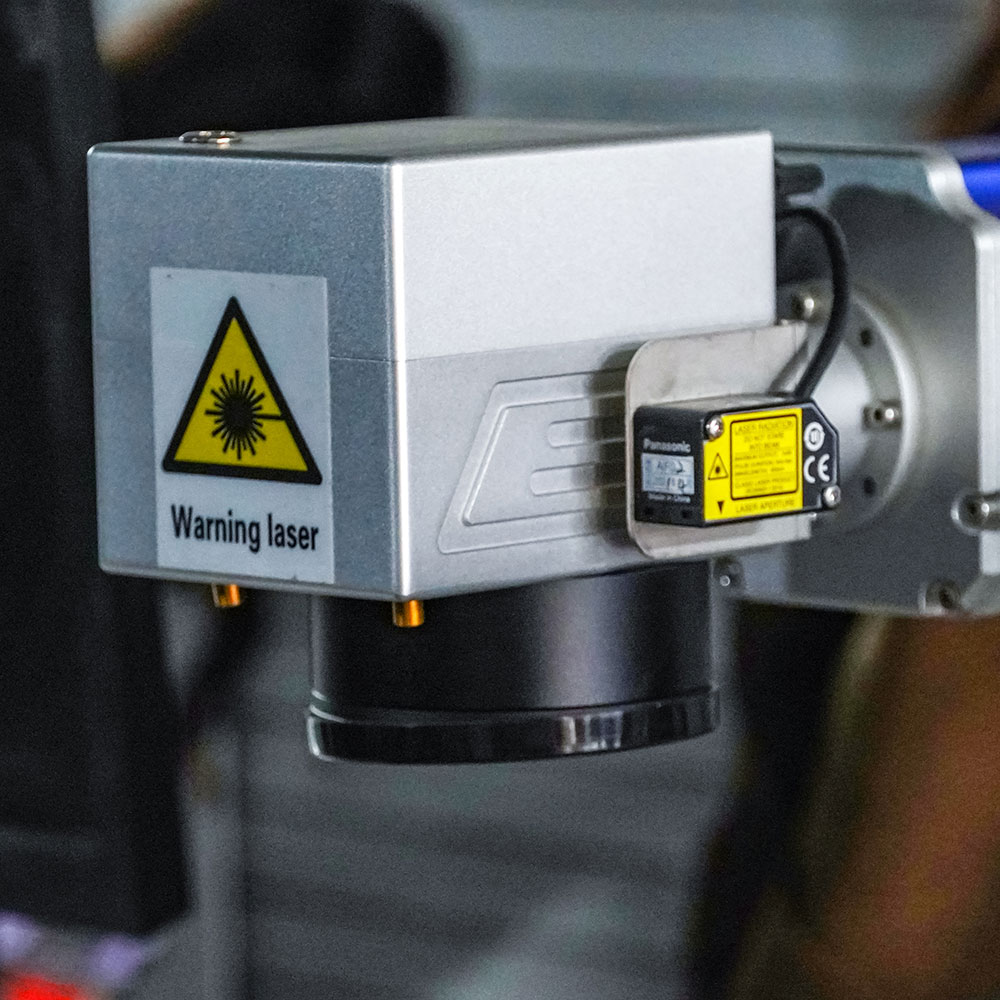

High speed scanning

Galvanometer with SINO technology

fast marking speed

high precision.

High quality and stable

Adjust the up and down for different height material marking

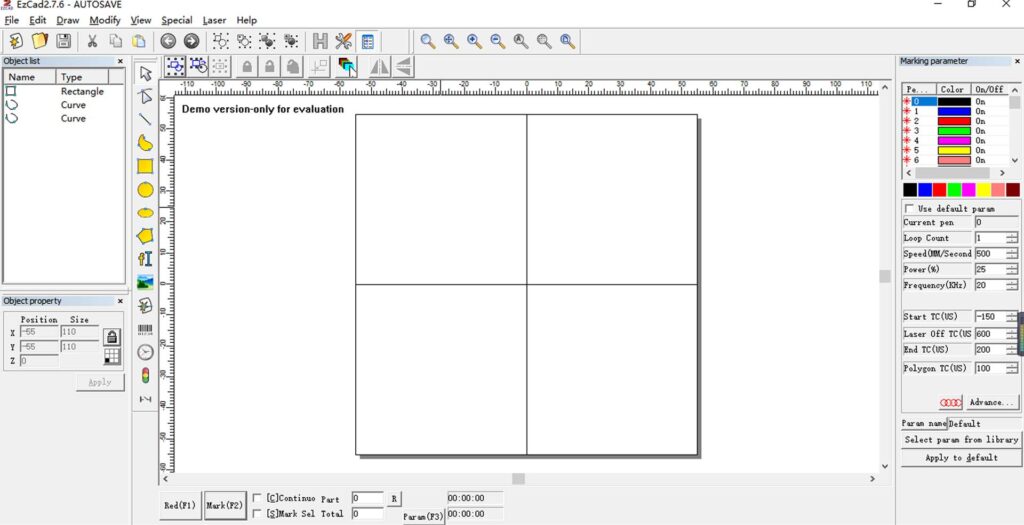

By ensuring user-friendliness in this aspect, we aim to minimize the learning curve and make it accessible to users of all levels of experience.

Provide a laser engraving and cutting experience that minimizes the cleaning requirements, allowing users to focus more on their projects and less on maintenance tasks.

Our laser engravers and cutters are equipped with powerful exhaust systems that actively capture and remove the byproducts of laser processing.

Laser systems offer extremely high precision and accuracy, allowing for intricate designs and fine details. This is crucial for tasks like engraving jewelry or creating intricate patterns.

| Laser Type | CO2 Laser, Fiber laser, UV Laser, Green Laser |

| Laser Power | 20W-100W |

| Laser Wavelength | 1064mm |

| Minimum Characters | 0.15mm |

| Repetition Accuracy | ±0.003mm |

A Laser Marking Machine is a device that uses laser technology to create permanent marks or engravings on a wide range of materials, such as metal, plastic, glass, wood, and more. It offers precise and high-quality marking, allowing for customization, branding, identification, and traceability purposes.

Laser Marking Machines work by directing a laser beam onto the surface of the material to be marked. The laser beam rapidly heats and vaporizes or oxidizes the material, leaving a permanent mark. The marking process is controlled by computer software, enabling the creation of intricate designs, text, barcodes, serial numbers, and other types of markings.

Laser Marking Machines offer several advantages. Firstly, they provide high precision and accuracy, allowing for intricate and detailed markings. Secondly, they are non-contact and non-mechanical, eliminating the risk of damage to the material being marked. Additionally, laser markings are permanent, resistant to fading, and offer excellent readability. Laser Marking Machines are also versatile and can be used on a wide range of materials. Lastly, they are efficient and can mark at high speeds, making them suitable for industrial production environments.

Laser Marking Machines have diverse applications across various industries. They are commonly used for product branding and identification, such as marking serial numbers, logos, and product information on consumer goods. Laser markings are also utilized in the automotive industry for part identification, traceability, and anti-counterfeiting measures. Additionally, the medical industry utilizes laser markings for surgical instruments and medical devices. Other applications include jewelry engraving, electronics marking, aerospace components, and more.

JQ LASER 2006 All rights reserved.

You will be responsed by our sales team very soon !

Наш отдел продаж ответит вам очень скоро!

¡Nuestro equipo de ventas le responderá muy pronto!

You will be responsed by our sales team very soon !